Our Material Guide Includes:

- Cardboard

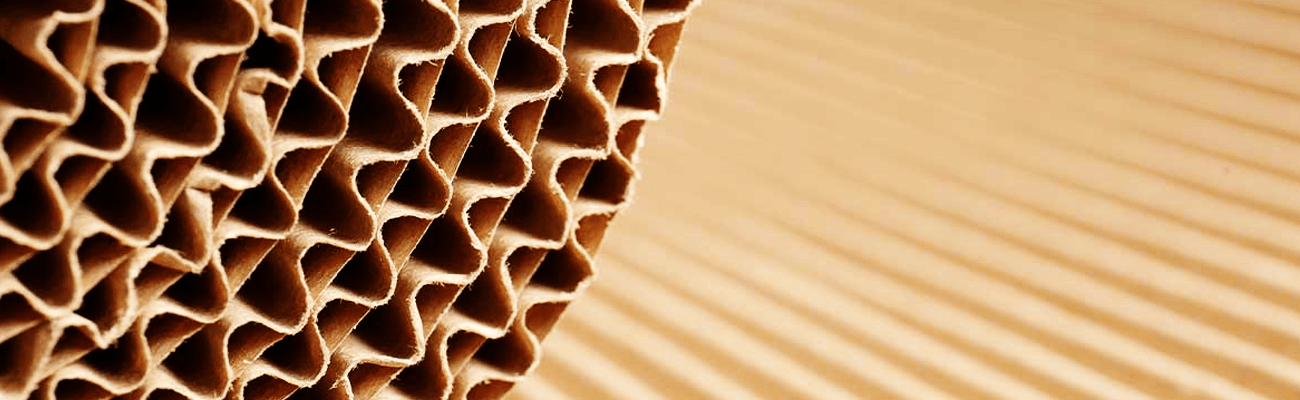

- Corrugated

- Flute Grades

- Rigid Materials

- Insert Materials

- Bag Materials

- Finishes

- Special Effects

- Print Options

Cardboard

- SBS C1S: Single-side coated folding box-grade material is primarily used in manufacturing boxes.

- SBS C2S: The dual-side coated material is often used for folding carton production due to its superior strength and flexible printability.

- Natural Brown Kraft: Made from unbleached, high-strength, and kraft pulp, providing superior strength and excellent printing properties.

- White Kraft: Paperboard material is considered environmentally friendly and made of virgin or recycled fibers.

- Black Kraft: An excellent choice for its rigidity, reliability, and affordability. It is a resilient and durable paperboard commonly used for packaging boxes.

- Uncoated Kraft: Natural and recycled paperboard made from wood pulp and kraft paper provides a stiff and robust paperboard that is perfect for various packaging and printing applications.

- Clay-coated Kraft: It is made by combining two layers of kraft paper and coating one side with a thin layer of clay. It provides excellent protection; its smooth clay-coated side makes it ideal for printing, labeling, and packaging.

- Metallic Paper: Metallic finish paperboard that has a shimmery, metallic look and is available in various colors. It provides a classy and modern accent to any project or product.

- Holographic Paper: Coated paperboard with light reflecting surface gives a unique three-dimensional effect to printed images, creating a captivating look.

- Textured Paper: Textured paperboard with small protrusions and indentations, creating a postcard-like appearance.

Corrugated

- Kraft Board: Strong and sturdy material composed of two brown layers of kraft paper, fluted to create an air cushion in between, and an inner liner sheet that provides extra protection.

- White Board: It is made from two smooth, flat sheets of paper separated by a rippled fluting pattern. It is lightweight, strong, and resilient, and its unique design makes it versatile for various packaging and shipping needs.

Flute Grades

- A-Flute: It comprises two flat layers of paper with an arched interior fluting layer in between. A-Flute is also lightweight, cost-effective, recyclable, and versatile in design.

- B-Flute: It is composed of two liners and a central fluted medium. It provides excellent product protection due to its cushioning, stacking strength, and superior printing surface.

- C-Flute: It is made with three stacked layers of paper. Its curved shape adds strength, rigidity, and protection to the packaging. It is lightweight and highly resistant to punctures and tears.

- E-Flute: It is made from two layers of the linear medium combined with a third layer of inner ply, usually with a fluting structure which gives it its name. This structure helps to make it highly flexible, lightweight, and strong.

- F-Flute: Features a fluted pattern of two layers of paper with a sheet of rippled paper in between. It is often used to package a product for added protection or extra cushioning.

Rigid Materials

- Grey Chipboard: Heavy-duty cardboard made of recycled paper pulp. It is mainly used for luxury packaging due to its rigid form, low cost, and range of colors available.

- Duplex Chipboard: Paperboard comprises two layers of paper, usually with a buffered or white bond paper in between. It is more robust, thicker, and heavier than regular cardboard.

Insert Materials

- Foam: It feels soft but is strong enough to give support and protection.

- Cardboard: Material made of thick, stiff paper that is often used to make box inserts.

- Corrugated: A type of cardboard that is stronger and more protective than regular cardboard. It protects unique things, like electronic devices, so they stay safe.

- Kraft: Protects products while also being affordable, durable, and lightweight.

- Rigid: A material used to make inserts that need to be strong and not wear out when facing high temperatures and pressures.

Bag Materials

- Paperboard: It is perfect for producing quality paper bags; it is thick, available in various colors and finishes, and has excellent printability, making it ideal for creating customized branding and promotional designs.

- Kraft Paper: Paper made from recycled materials is strong and can resist water. It usually looks brown.

- Metallic: Luxurious and striking material that has become increasingly popular in recent years. It has a beautiful reflective sheen, is lightweight and durable, and is available in a range of attractive metallic colors.

- Holographic: This particular kind of paper is shiny and reflective and looks fantastic.

- Textured: This exceptional paper is strong and has designs that make it look stylish. It's perfect for creating beautiful bags with lots of things.

- Polyethylene: It makes waterproof bags that won't rip or tear easily. It is strong enough to hold the light to moderately heavy items.

- Polyethylene Terephthalate: PET is a strong and clear material used to make reusable and single-use bags. It is eco-friendly since it can be recycled. The bags made from this material are durable and can hold heavy items!

Coatings and Laminations

- Gloss: Creates a more vibrant and eye-catching printed product, preventing smudging, fingerprinting, and other types of damage. This is usually done to protect against dust, moisture, and other environmental factors and provides an extra layer of durability to the printed product.

- Matte: Produce a non-reflective surface; it creates a durable and protective finish that enhances the appearance and longevity of the printed product.

- Soft Touch: It makes things feel slippery and smooth and also makes them last longer.

Special Effects

- Hot Foil Stamping: This is a process that makes the paper look fancy. Heat and pressure stick a shiny metal material onto the paper. This creates a unique effect that can make the paper look more impressive.

- Embossing: A technique that uses a combination of pressure and heat creates an indentation in a paper material. It is frequently used to add texture and create myriad unique designs and patterns.

- Debossing: It is a way to make images or designs on materials using a die that pushes the image onto the material and leaves a raised or indented image.

- Window Patching: This is a way of packaging things, so you don't have to open the box to see what's inside. You can see it through the clear plastic window on the front or side.

- Spot UV: A unique printing process adds a shiny coating to parts of a design to make them look unique. It can give the design more shine, texture, and contrast.

Print Options

- Offset: Offset printing is a way to make prints of high quality. It involves transferring ink from a plate to a rubber blanket and paper. It's usually used for many prints at once.

- Digital: Digital printing is making prints using ink and machines that are very fast and easy. It makes better images than other ways of printing, and it is less expensive for small orders.

- UV Print: Ultraviolet printing is a type of printing that uses special ink that bonds to paper or plastic when exposed to ultraviolet light. It makes prints that won't fade away and resist water and chemicals.

- Water-Based Ink: Water-based ink is a particular type of printing ink made from water and pigment instead of chemicals like traditional ink. It is safer and better for the environment and makes bright and colorful prints. You can use it on all kinds of materials like paper and plastic.

- Soy-Based Ink: Soy-based ink is an eco-friendly print method that uses plants to make colors look vibrant and smooth. It helps the environment by being easily recycled and costing less than other printing types.

- Oil-Based Ink: This kind of printing uses special inks that aren't ruined by rain or sunlight, making them perfect for outdoor signs.

- Pantone (PMS): The Pantone color system gives printers and designers special codes to match colors. The codes help them ensure that all the colors look the same in different prints. The colors are exact and bright and can be combined to make other colors.

- Metallic: Metallic printing is a type of printing that uses special foil to put text, logos, images, and other designs onto items. It looks gleaming and lasts a long time.